The concept of an efficient server room was pioneered overseas and in recent years has been recognised by an increasing number of industry professionals and owners in China, and its applications are becoming more and more widespread.

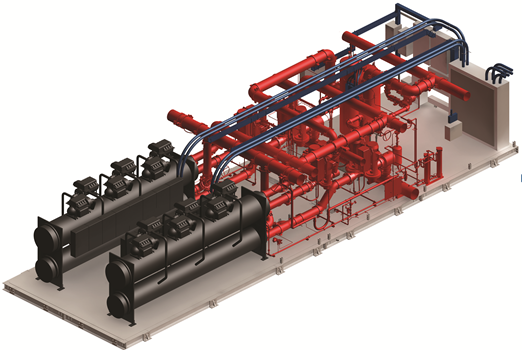

IPP-CHW is a factory pre-installed system solution, with an energy efficient control system as the core, integrating all associated equipment into one model, using integral structural design ideas, applying integrated wiring technology, computer network technology, integrating all equipment, functions and information into an interrelated, unified and coordinated system. Optimised equipment selection and piping resistance, fast installation and easy maintenance, widely used in commercial and industrial cooling water cooling systems.

The Armstrong Ultra High Efficiency Integrated Chiller Plant combines all the necessary equipment to deliver chilled water to medium to large buildings with outstanding energy efficiency. Factory assembled equipment includes pumps, integrated controls, water cooled chillers and the necessary instrumentation, valves and sensors. IPP meets all ASHRAE 189.1 requirements and exceeds ASHRAE 90.1.

Strengths and features

01Lower installation costs

Factory designed, manufactured and tested equipment kits are quick and easy to install, reducing commissioning costs by up to 25% compared to equivalent units supplied with individual components.

02Lower operating costs

Complete pre-assembled units, combined with better matching and adjustment of components, can save up to 50% (0.5 kW/ton) of energy compared to conventional cooling water plant units.

03Lower environmental costs

Better demand-based plant performance can improve energy efficiency by up to 50% (0.5 kW/ton) and reduce carbon (greenhouse gas) emissions (avoided electricity generation) by up to 50% compared to conventional chilled water plant installations.

04Lower project and operational risk

Products are designed, assembled and tested in a controlled ISO 14000 factory environment to ensure trouble-free installation and continued lifetime performance.

ECO*Pulse™ HVAC health management service (including predictive maintenance) is free for the first year and reduces equipment breakdowns and downtime.

Single source responsibility for project and product support can be ensured.